Diazo, also known as “light printing”

In 1923, the German Kalle & Co introduced a photoprinting process based on light-sensitive diazonium and azo compounds. This creates a positive print of reddish-brown lines on a white background. Quite an improvement compared to the negative diazo copies.

compounds. This creates a positive print of reddish-brown lines on a white background. Quite an improvement compared to the negative diazo copies.

This process, which uses two chemical components, was invented and patented by Kalle in 1921.

Louis van der Grinten sees this new process as a major threat to the blueprint process. That is why Van der Grinten also starts the production of such two-component diazo materials under the name “Primulin”.

Louis van der Grinten sees this new process as a major threat to the blueprint process. That is why Van der Grinten also starts the production of such two-component diazo materials under the name “Primulin”.

.

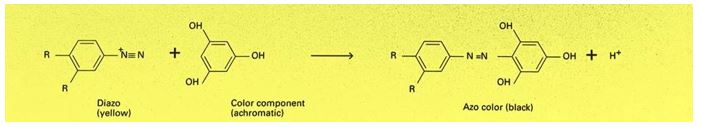

The Diazo Process

In Diazo processes, two substances are needed for imaging, namely a light-sensitive Diazo compound and a so-called coupler. These two substances enter into a chemical reaction during development and form a (dark) azo dye.When exposed to ultraviolet light, the blueprint compound chemically disintegrates so that it can no longer form a dye with the coupler. Where no light has fallen, the diazo compound remains intact. Here, a dark image can be created by reaction with the coupler.

Because the diazo compound is only sensitive to ultraviolet light, the diazo paper can be processed under normal office lighting.

Diazo dyes are very stable. That is why diazo copies have a very long shelf life. Copies from around 1920 are still easy to read.

In the Kalle process, a mixture of the diazo compound, the coupler and a buffer compound is made. The buffer compound is intended to prevent the coupling reaction, but becomes inactive in an alkaline environment. This mixture is coated on the copy paper. After exposure, the paper is exposed to ammonia vapor which neutralizes the buffer, after which the color reaction begins.

Initially, Van der Grinten’s Primulin process works in the same way.

Océ paper, Van der Grinten’s product

When Kalle notices Van der Grinten’s activities, it sues its Venlo competitor for infringement of its patents and demands termination of sales. Kalle joined the industrial conglomerate I.G. in 1925. Farben, and therefore poses a serious threat to the small company Van der Grinten.

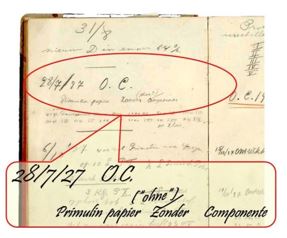

Louis van der Grinten then looks for a way to circumvent the Kalle patents. This was achieved in 1927.  Instead of applying the diazo and the coupler mixed on a paper carrier, he split the diazo and coupler.

Instead of applying the diazo and the coupler mixed on a paper carrier, he split the diazo and coupler.  The light-sensitive diazo compound is coated on the paper and the coupler is added as a (water-based) developing liquid after exposure.

The light-sensitive diazo compound is coated on the paper and the coupler is added as a (water-based) developing liquid after exposure.

Van der Grinten supplies copiers with moistened rollers for developing, but the developer can also be applied by hand if necessary.

Van der Grinten in turn applied for a patent for this process variant in 1927. A first patent was granted in 1930.

The advantage of the new technology is that a positive copy can be made without ammonia vapor, which has an unpleasant smell. Diazo paper was marketed in 1928 under the brand name “Océ”.  This name is an abbreviation of the German expression “Ohne Componente”, which further emphasizes the difference with the Kalle product. Louis uses this term in his laboratory journal in 1927.

This name is an abbreviation of the German expression “Ohne Componente”, which further emphasizes the difference with the Kalle product. Louis uses this term in his laboratory journal in 1927.

In the beginning this is abbreviated to O.C. and shortly afterwards registered as the “Océ” trademark. The “é” has been added for administrative reasons and also makes pronunciation even easier.

registered as the “Océ” trademark. The “é” has been added for administrative reasons and also makes pronunciation even easier.

By using different developing fluids, prints of different colors can be made.

The process will be further refined later. The Van der Grintens then devised the “semi-dry Diazo process”, in which the developing liquid can be applied in such a thin layer that a separate drying process is no longer necessary.

The name “Océ”, initially intended for one product, was later (1970) used for the entire company.

Blueprint and diazo continued to exist side by side until approximately the end of the Second World War. The exposure equipment from that time is suitable for both blueprint and Blueprint material.

The exposure equipment from that time is suitable for both blueprint and Blueprint material.  With diazo, a separate developing device is still required for liquid development. Around 1950, Van der Grinten introduced combined exposure and developing machines, the so-called ‘combines’.

With diazo, a separate developing device is still required for liquid development. Around 1950, Van der Grinten introduced combined exposure and developing machines, the so-called ‘combines’.

After the Second World War, diazo conquered the entire drawing room market.

In the drawing room, translucent originals are produced (drawings on ‘calques’) precisely in order to be able to use these copying processes. Van der Grinten develops various products for this purpose, based on paper and transparent materials.

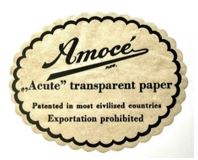

The transparent material ‘acute’ is very successful in the market, because sharper copies can be made with it than with regular paper.

The transparent material ‘acute’ is very successful in the market, because sharper copies can be made with it than with regular paper.

In addition to copying systems for the drawing room, there is also a demand for copying systems for office applications. However, this usually produces non-transparent documents, which are difficult to copy with blueprint material.

Van der Grinten will also develop solutions for this.

Diazo copying in the office >> click here