Coloring for butter and margarine

Natural butter has a yellow colour in summer, but a much lighter colour in

winter, when cows are stabled and eating only hay. To make their product more attractive, farmers and butter merchants traditionally coloured their butter with food colouring in winter.

Margarine, developed in 1869 in France, has a light grey colour by itself. To make the product look more like butter, a dye was applied to make it more appealing to consumers.

Various dyes have been used over time, both natural and synthetic.

Natural coloring agents

Natural coloring agents for butter and margarine are often based on carotenoids.

Examples are carrot zest and annatto. Turmeric was also used.

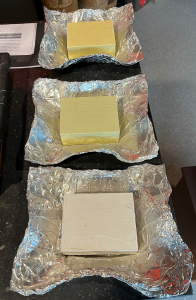

Carrot grater

To color winter butter, farmers traditionally used an extract from red carrots. From a recipe booklet from the 1860s: “Take carrots that are as red as possible, wash them and grate them with a knife without touching the top. Take fresh milk, still warm, put the grated carrots in it, stir it, strain it by squeezing it through a linen cloth, add it to the butter and mix it. One grated carrot is enough for a kilo of butter.” This simple coloring process gave a slightly different result each time. However, within the small-scale economy, differences in colour, smell and taste were not objectionable.

To color winter butter, farmers traditionally used an extract from red carrots. From a recipe booklet from the 1860s: “Take carrots that are as red as possible, wash them and grate them with a knife without touching the top. Take fresh milk, still warm, put the grated carrots in it, stir it, strain it by squeezing it through a linen cloth, add it to the butter and mix it. One grated carrot is enough for a kilo of butter.” This simple coloring process gave a slightly different result each time. However, within the small-scale economy, differences in colour, smell and taste were not objectionable.

.

.

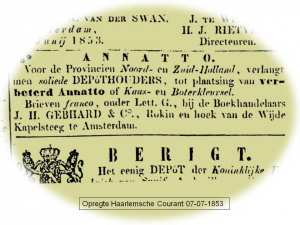

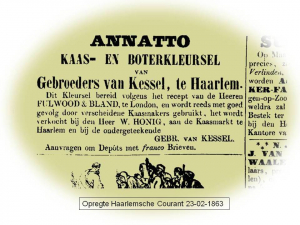

Annatto

Anatto is a natural coloring agent derived from the seeds of the orlean tree

(Bixa orellana) and has been used for centuries to color food and other products. The plant occurs in tropical parts of Latin America and was introduced to Europe in the sixteenth century by Francisco de Orellana, a participant in Pizarro’s expeditions in northern South America.

Annatto was imported into the Netherlands from the West Indian colonies as early as the 17th century, originally as a pigment. In 1743 it was mentioned in the Huishoudelyk Woordboek as a coloring agent for cheese.

.

Opregte Harlemse Courant 07-07-1853

Annatto contains two carotenoid dyes, the red bixin (a fat-soluble component) and the yellow norbixin (soluble in water). Both dyes are used in butter.

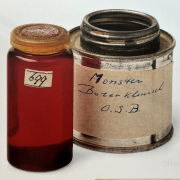

Cheese and butter coloring factories from anatto seed are first reported in Denmark, and since 1860 also in the Netherlands. There were several producers.

.

.

.

.

.

Turmeric

Turmeric is extracted from the tropical plant curcuma longa, native to India

and Southeast Asia. There, it is traditionally widely used as a colouring agent in oriental dishes such as curry. In addition, it is/was widely used worldwide as a food dye, including in butter.

The active dye is known as curcumin. In an acidic environment the colour is bright yellow, in an alkaline one it turns brown. The colour is not very lightfast.

Synthetic dyes

Synthetic dyes for margarine enter the market around 1890. 60-70% of all dyes used in the food industry are so-called azo dyes. Azo dyes are stable at all pH values found in foods, are heat-stable and are not sensitive to light or oxygen. This makes them much more stable than most natural dyes. Therefore, they can be used in almost all foods.

Synthetic dyes for margarine enter the market around 1890. 60-70% of all dyes used in the food industry are so-called azo dyes. Azo dyes are stable at all pH values found in foods, are heat-stable and are not sensitive to light or oxygen. This makes them much more stable than most natural dyes. Therefore, they can be used in almost all foods.

The production of azo dyes is cheap because most of the raw materials for them are cheap and because the production process is simple. This was especially attractive for margarine, another cheap product. In butter, chemical dyes were hardly used, if at all.

Over the years, it turned out that many of these synthetic colourings can have an adverse effect on health, which is why their permitted amount in food has been increasingly restricted.

Van der Grinten and butter colours

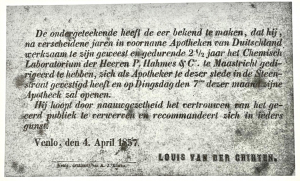

Lodewijk van der Grinten (nickname Louis) opened a pharmacy in Venlo in 1857.

Like many fellow pharmacists, Lodewijk van der Grinten supplies colouring agent for butter in small quantities (15g bottles) locally to farmers.

At the time, the dye is based on turmeric and orlean (annatto). He sources the annatto from South America and especially from the Caribbean.

At the time, the dye is based on turmeric and orlean (annatto). He sources the annatto from South America and especially from the Caribbean.

Over time, pharmacists in the region increasingly source their colouring from Van der Grinten, who apparently provides a good and cheap product. By the end of the nineteenth century, Van der Grinten has an established position throughout central and southern Netherlands.

.

In addition, a new market was created by the rise of butter factories

around 1870 and, a little later, cooperatives, which required larger quantities of butter colouring of uniform quality. Lodewijk van der Grinten managed to establish a position here too, despite fierce competition from abroad, such as Denmark (Hansen, 1874), England, Germany and Belgium.

From 1874 onwards, he produced the colours factory-wide, already in batches of 600 kg in 1877.

.

Another development also offers opportunities for increasing sales: the introduction of margarine. It was invented in France in 1869 by Hippolyte Mège Mouriès as a cheap butter substitute and went on sale in Paris the following year. The major butter traders, such as Jurgens in Oss, will soon also produce this, under license or by circumventing Mège Mouriès’ patent.

.

.

.

.

.

.

At the end of the 1880s, Van der Grinten started using the azo dyes

that were then coming onto the market as a coloring for margarine, in addition to the more expensive annatto product. In the course of 1895, Frans Van der Grinten, third son of Lodewijk and pharmacist since 1877, and active in the company since 1890, conducted an extensive series of experiments with azo dyes. The acquired knowledge and experience will later be useful to the company when developing the diazo copying system. The production process for synthetic butter coloring is more complicated than that for annatto, but the product is cheaper.

It will be produced until 1949, when it becomes clear that these substances can be harmful to health.

From 1890, the Van der Grintens also turned their attention abroad and expansion was rapid. It starts in Germany, Austria and Switzerland, and then moves southwards. Within a few years, there are also trade contacts in England, Canada, the United States and even Australia. The pharmacy becomes too small for production and is formally separated from the factory in 1890.

In the factory, Lodewijk van der Grinten and a servant produce the colouring. Frans runs the pharmacy, assisted by a highly qualified servant, Hendrik Meuskens, but also does promotion for the butter colouring. The pharmacy is expanded for production.

In 1899, the pharmacy is moved to another location in Venlo and later sold to cousin Wiel van der Grinten. The old location is extensively rebuilt for colouring and in 1901 a new factory for colouring is built on the Hoge Weg, then on the outskirts of Venlo.

In 1899, the pharmacy is moved to another location in Venlo and later sold to cousin Wiel van der Grinten. The old location is extensively rebuilt for colouring and in 1901 a new factory for colouring is built on the Hoge Weg, then on the outskirts of Venlo.

Lodewijk van der Grinten suffers from asthma and his health continues to deteriorate. For this reason, his son Frans gradually takes over the management of the company from 1890 onwards. Lodewijk dies in 1895.

.

.

.Due to prolonged exposure to the synthetic dyes, workers develop a yellowish

complexion. They are popularly called “canaries”. Frans van de Grinten therefore develops a protective compressed-air mask that prevents inhalation of the dye. He receives national recognition for this early “environmental measure”.

.

.

Against a lot of competition, the Nederlandsche Boterkleurselfabriek manages to hold its own through a great deal of research and development and by actively responding to new developments and customers’ wishes.

In addition to butter colouring, the company increasingly focuses on other products.

In 1970, the formula and the production facilities were sold to the largest customer, Jurgens en van den Bergh, now part of Unilever. By then, butter colouring was only a small part of the company’s operations and hardly contributed to its profits.