Electrophotography is based on creating an image of static charge on a master and developing that image with (black) toner particles that are attracted by the static charge.

The master is a sheet of carrier material (paper), plate, tape or drum, covered with a semiconducting layer that is electrically insulating in the dark and becomes conductive when exposed, the “photoconductor”.

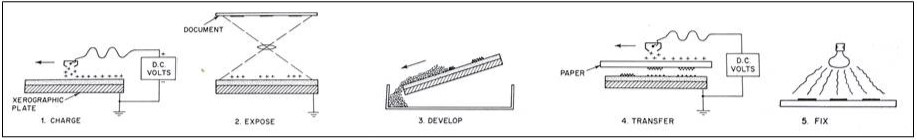

In the image-forming process, the photoconductor is charged in the dark (1) with a spray electrode (corona) or a current-carrying roller.

The charged photoconductor is then image-wise exposed (2), leaving a charge image on the photoconductor.

The photoconductor is then brought into contact with electrically charged toner particles, which adhere to the charged parts of the photoconductor (3). Toner particles get their electrical charge through friction with iron powder that is mixed with the toner particles. Iron particles (also called carrier particles) are not attracted to the charge image and therefore remain in the development system to be reused. They can be easily manipulated using a magnet. In other systems, toner particles are dispersed in a suitable insulating liquid (e.g. kerosene), in which the toner particles are also charged by movement.The toner image is then fixed directly to the photoconductor (“direct electrophotography”), or transferred (4) to a sheet of paper and fixed thereon (5) (“indirect electrophotography”).

The photoconductor is then brought into contact with electrically charged toner particles, which adhere to the charged parts of the photoconductor (3). Toner particles get their electrical charge through friction with iron powder that is mixed with the toner particles. Iron particles (also called carrier particles) are not attracted to the charge image and therefore remain in the development system to be reused. They can be easily manipulated using a magnet. In other systems, toner particles are dispersed in a suitable insulating liquid (e.g. kerosene), in which the toner particles are also charged by movement.The toner image is then fixed directly to the photoconductor (“direct electrophotography”), or transferred (4) to a sheet of paper and fixed thereon (5) (“indirect electrophotography”).

Electrophotographic systems

Electrofax

An early form of electrophotography is electrofax. This process was developed in the 1950s by the company RCA. A sheet of paper with a zinc oxide coating is electrostatically charged, exposed and developed with liquid or dry toner. It is essentially a “direct” process.

Electrofax machines are relatively simple, the copy material is cheap, but the copies have a low density and poor area filling. The photoconductor material zinc oxide is completely safe in human contact.

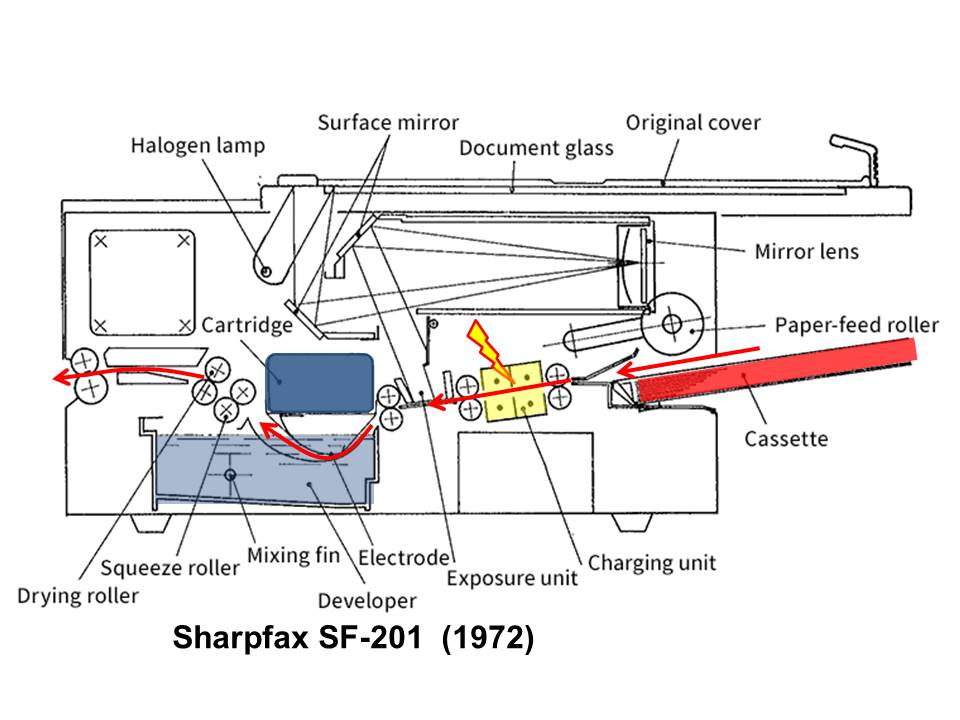

Xerography

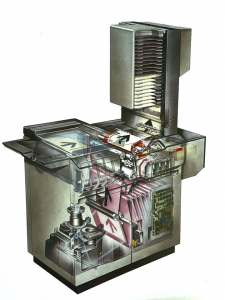

Xerography was invented in 1936 by Chester Carlson in Rochester, USA. This system uses a photoconductor permanently attached to the device that is repeatedly charged and developed. Carlson uses vapor-deposited selenium for this. The toner image is then transferred to a sheet of paper and fixed on it to form a copy. Xerography is therefore an “indirect” process, and is also called “plain paper copying”.

Xerography was invented in 1936 by Chester Carlson in Rochester, USA. This system uses a photoconductor permanently attached to the device that is repeatedly charged and developed. Carlson uses vapor-deposited selenium for this. The toner image is then transferred to a sheet of paper and fixed on it to form a copy. Xerography is therefore an “indirect” process, and is also called “plain paper copying”.

.

.

The first commercial application was a flat-plate copier offered by The Haloid Company (later Xerox Corp.) in 1950. Xerographic machines are relatively complex, the copy material is still cheaper, and the blackening and area filling are clearly better than in electrofax. The photoconductor material selenium is poisonous, but in principle does not come into contact with the operator.

(later Xerox Corp.) in 1950. Xerographic machines are relatively complex, the copy material is still cheaper, and the blackening and area filling are clearly better than in electrofax. The photoconductor material selenium is poisonous, but in principle does not come into contact with the operator.

Océ and electrophotography

Initially, the Van der Grintens are sceptical about electrophotography. They study the process, but find that it is complicated and too sensitive to humidity, and that the development costs will exceed Océ’s financial resources. Nevertheless, Océ starts research in 1965, because the developments in the USA are fast and successful. The first project is the Océ 1500, which is based on dry electrofax.

The Océ 1500 is marketed in 1968, but is not successful.

Four years later, Océ switches to the development of indirect electrophotography.

Four years later, Océ switches to the development of indirect electrophotography.

In the meantime, the electrophotography market is served by two acquisition products from Minolta, known as the Océ 1100 and Océ 1415, both based on liquid electrofax (under license from RCA). The Océ 1250 is also added, a table-top device based on dry electrofax. This device is made by the American company ICP, which has been taken over by Océ.

These devices work with copy paper with a zinc oxide coating, which is produced in Venlo.

.

.

The research into indirect electrophotography yields the Océ 1700, which is introduced in 1973.  An internal photoconductor based on zinc oxide is used in this machine.

An internal photoconductor based on zinc oxide is used in this machine.

For this, the knowledge of such material from the production of copy material for electrofax products can be used. Because zinc oxide needs a recovery period after each copy, the master consists of 800 image places that are used one after the other.

For this, the knowledge of such material from the production of copy material for electrofax products can be used. Because zinc oxide needs a recovery period after each copy, the master consists of 800 image places that are used one after the other.

The development is based on so-called binary toner, a mixture of toner and iron powder.

.

.

A major improvement in quality is made with the Océ 1900, which has an improved zinc oxide master and uses unary toner, a semiconducting powder, that no longer contains iron particles.

and uses unary toner, a semiconducting powder, that no longer contains iron particles.

A new transfer method for the toner from the photo-conductor to the copy paper is developed: “Transfer Transfuse” (TTF).

The above-mentioned electrophotographic devices are all intended for the office market. When their success increases, Océ also applies the process with unary toner in wide-format devices. A breakthrough is achieved with the Océ 7500, a wide-format copier that gives Océ an important market position.

The above-mentioned electrophotographic devices are all intended for the office market. When their success increases, Océ also applies the process with unary toner in wide-format devices. A breakthrough is achieved with the Océ 7500, a wide-format copier that gives Océ an important market position.

.

.

.

A further improvement is then achieved with a new photo-conductor based on vapour-deposited organic material, which has a much longer life. This new material must be produced in a dust-free environment.

which has a much longer life. This new material must be produced in a dust-free environment.