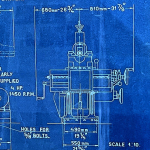

Blueprint

Blueprinting (cyanotype) was invented in 1842 by English photographer John Herschel. As a light-sensitive layer, Herschel used a mixture of potassium hexacyanoferrate and ammonium iron citrate, which, when exposed to strong ultraviolet light, changes into Prussian blue. Then, when the chemicals are washed away with water, a stable blue color remains, while the unexposed areas remain white.

Herschel’s light-sensitive paper had a shelf life of several weeks when unexposed. Application was mainly in the artistic world. Anna Atkins (1799 – 1871) was the first to publish photographic books made with Herschel’s process.

Application in industry

By the end of the nineteenth century, shelf life had improved to one year. This made possible the use of blueprint paper for making copies of architectural and engineering drawings, freeing draftsmen from the time-consuming work of making copies, also known as calquering.

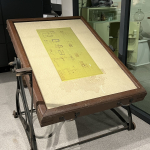

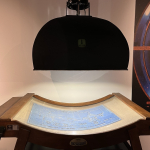

To make a copy, a translucent original must be placed on the blueprint paper. Exposure by sunlight or ultraviolet lamplight (arc lamps) then takes place through the original.

The blueprint process had the advantage of being relatively inexpensive. As a print one received a negative: the lines were white on a blue background. The print had to be washed with water after exposure, which was difficult and time-consuming when sheets were large.

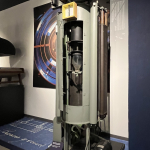

The users of copy papers were largely found in industry and in particular in such industries as the machine industry, shipbuilding, electrical engineering, and residential and commercial construction. Since 1890, there had clearly been an expansion of industry in the Netherlands. The number of people employed in Dutch industry increased from 380,000 to 880,000 between 1889 and 1947. Also, the increase in the complexity of technical products increased the need for construction drawings and copies thereof.

In the Netherlands, blueprint paper was already offered in the nineteenth century by several companies, such as Ahrend (Amsterdam) and Immig (Rotterdam), in different, sometimes seasonally dependent, light sensitivities. In addition, automated exposure machines entered the market.

Van der Grinten and blueprint

In the First World War, the leader of the butter coloring factory, Frans van der Grinten, started thinking about expanding production with a new product. In 1918, for example, his son Louis conducted experiments with curtain dyes. At the same time, literature was collected on how to make blueprint papers. Essential in the manufacture of blueprint paper was the composition of the liquid with which the raw paper was prepared. Chemical knowledge and laboratory research were required to design a preparation with the right properties. Applying the layer of liquid to a raw material paper, the so-called preparation, was in principle a simple technique that mainly required traditional knowledge.

Louis van der Grinten searched for recipes in the literature and started his own experiments. He also ordered exposure equipment and the blueprint paper from the various competitors.

Louis did not limit himself to imitating existing products, but tried to make a product with improved properties. Venlo was unfavorably located for the production and sale of the unsustainable fast-acting blueprint paper on the Dutch market. That is why he focused his research on increasing the light sensitivity of long-life paper.

In 1919 Van der Grinten started production. The first sheets were prepared by hand, and on December 5th 1919 the first preparation machine was introduced.

In addition to the durability and light sensitivity of the paper, the clarity of the lines and the darkness of the blue were important factors in sales. Since it was difficult to optimize these requirements, a balance of interests had to be made. This led to Van der Grinten already offering the blueprint paper in six different qualities after a few years.

In the meantime, research was done into the possibilities of reproduction with other chemicals.

(source: Van Boterkleursel naar kopieersystemen, ISBN 90 68903 394 2)